|

|

Standing still is not an option.The old ways will cost more and will foul our world |

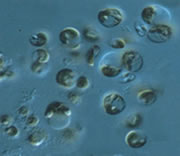

Home >> FAQ'sThese are a few of the questions we field frequently. Please email us your questions and we will update this page as we can. Sustainability is not just a dreamy ideal. We are already seeing depleted fish stocks, exhaustion of soil that requires ever-more-expensive fertilizers, overuse of surface water, exhaustion of water in deep aquifers, an expanding market for meat and other high-end food products in Asia, and increasing costs of energy that is used in agriculture and food distribution. All of these forebode a big increase in the cost of food to go along with increasing costs of basic power and transportation. All of these costs could be small by comparison to the costs of global warming Future regulations are certain to be put in place to deal with these threats and current regulations will actually be enforced. Sustainable processes are likely to make money in a world desperate for resources; unsustainable processes will fail as fast as alternatives can be found. There isn’t going to be a single magic bullet that solves all CO2 and waste problems, while insuring a renewable, non-polluting fuel supply. However, ALGACORE is an important part of the solution. ALGACORE can make a contribution to solving all of these problems and will save money for energy producers, aquaculture and livestock producers as well as industrial and municipal waste managers.Deep sequestering of CO2 is an incompletely proven process that has been proposed to make extensive burning of the abundant coal supplies environmentally acceptable. We should ask how long the CO2 that is buried will stay there? Is it a safe way of dealing with a major contributor to global warming? The economics of burying CO2 and cleaning other pollutants are also not clear. FutureGen was a joint US government and private coal company project to build a near zero-emissions coal-fueled power plant that disposed of CO2 by burying it. On January 29, 2008, the Department of Energy announced it was withdrawing funding from FutureGen, citing the doubling of costs and the need to revamp the plans. This technology, then, will take more years to come online, and even then is inherently more expensive than a system that uses algae to capture the CO2. ALGACORE asks: why bury CO2 when you could make money from it? We are recycling CO2 in processes that earn money, thereby avoiding the uncertainties of gaseous sequestering and offsetting the costs of removing sulfur and nitrous oxide.Corn is a fundamentally inefficient way of producing bio-fuels – so inefficient that it is possible to argue that it uses more energy than it produces. We should adopt a basic principle of not using food to power our cars. If for no other reason, the competition for limited water and arable land will make the economics of corn-based ethanol ever more marginal, making it very difficult to recapture the substantial capital costs in the future. Cellulose-based systems are theoretically more efficient and can use crops, such as switchgrass, that do not require prime arable land. However, algae, being a very simple organism, can grow more efficiently by orders of magnitude. Algae is the right level. It is efficient, can be grown on any land close to sources of CO2 and waste nutrients, and with the speed and effectiveness of ALGACORE technology, it can do its work on a small footprint. The industrialization of algae, through ALGACORE, has properties that no other technology does. Further, the basic technology is scalable from very small installations to major power-plant size applications. Small scale trials are so fast and relatively cheap that it would be imprudent to not do further investigation. Like most new technologies, this is an area in which much more is promised than delivered. However, Round River Technologies has demonstration projects underway in both Canada and the United States that make it easy for you to see the process in operation. Please contact us for further information |