|

|

Sustainability requires us to produce food without destroying resources.Our process produces this sustainability under the intensive conditions of commercial agriculture |

Home >> Food ProductionWaste treatment for feedlot and dairy livestock operations:

Manures produced by feedlot and dairy operations in the U.S., Canada and elsewhere are a major source of the greenhouse gases methane and carbon dioxide (CO2) as well as noxious odors and severe water pollution. The growth and even the maintenance of these food-producing operations are critically threatened by civil suits and restrictive government regulations. ALGACORE’s integral Anaerobic Digestion processor coupled with ALGACORE’s core processes transform all of these pollutants into energy and raw materials useful to a wide range of industries, from construction materials to organic fertilizer and livestock feed production Recirculating aquaculture pollution control and feed productionALGACORE provides 95% water recirculation for finfish and shellfish production from the nursery to full grow outs. The pro-biotic nature of ALGACORE’s living-filter technology (ALGACORE "mix" process) markedly improves fish health compared to conventional recirculating aquaculture technologies.

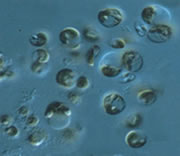

The improved fish health occurs first, because our system incorporates two paths for reducing unwanted bacterial populations. Our uniquely high growth rates of niche-adapted algae put extraneous bacteria at an intense disadvantage in competition for resources. In addition, using our proprietary technology, we adapt probiotic (friendly), niche-specific bacteria. These bacteria form a persistent symbiosis with the algae, again putting unwanted bacteria at a disadvantage, precluding any substantial growth. Viruses are extensively inactivated by the endocytosis (engulfing within the membrane wall) of the much more numerous algae and probiotic bacteria. The ammonia produced by breakdown of the organic material is readily oxidized by the bacteria and the oxygen produced by the high concentration of algae in this “greenwater” system. These conditions produce a particularly effective version of the well-understood dynamics that occur at a much slower rate in the oxidation ponds conventionally used to break down unwanted biological material. The refined greenwater conditions, sustained by our proprietary technology, allow fish to be raised in concentrations up to three times higher than conventional and still be far less stressed than fish raised at high concentrations in clear-water systems Overall then, both growth rates and culinary quality are greatly enhanced, while reducing the need for the costly pharmacological interventions that are all too common in conventional aquaculture. ALGACORE’s process also produces a HUFA-rich fish feed supplement concurrently with the water treatment. This sustains fish health while substantially reducing fish-feed costs. These savings and improved quality can be passed along to the consumer. |